Wear parts

Location : Home > PRODUCTS > Wear parts >

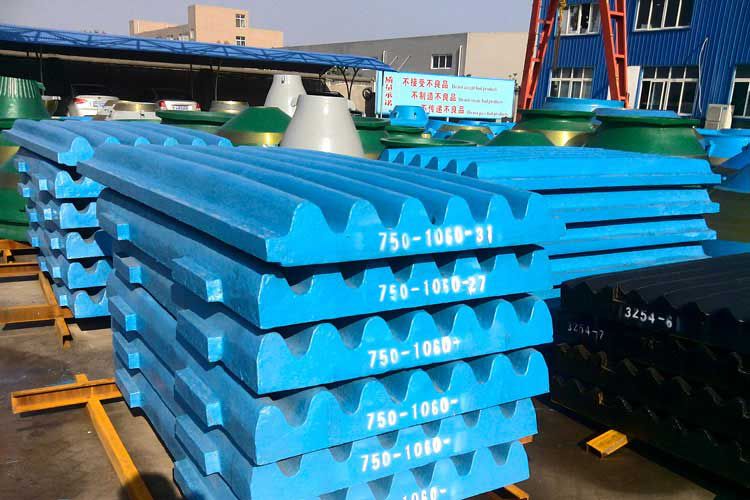

HSI Impact Crusher parts

- Common Aliases:Blow bars, HSI Blow Bars, high chrome hammer, high manganese steel hammer

- Main Material:high manganese steel, high chromium (Cr13, Cr23, Cr26, Cr28 etc.)

- Casting Technology:sand casting, lost foam foundry, v-process foundry

- Applicable Materials:coal gangue, river gravel, granite, basalt, iron ore, limestone, quartz, diabase

- Applications:gravel quarry, mining, coal mining, concrete mixing plants, dry mortar, desulfurization plant

PRODUCT DESCRIPTION

High chrome Blow bars

For working conditions and the structural characteristics of large-scale counterattack crusher, JYS developed ultra-high chromium cast iron plate with a hammer comprehensive high wear resistance, service life is greatly improved. Compared with similar products, high chrome casting JYS hammer with high safety, wear resistance, low cost, etc., and shorten lead times.

High manganese steel Blow bars

A modified high manganese steel casting, reasonable ratio of ingredients, more secure and reliable plate hammer, not only reduces downtime, and improve the operation rate increase crusher production, reduce material costs.

Composite board Blow bars

Using technology to produce mosaic wear-resistant alloys. In order to improve the wear resistance, the traditional hammer and more common in the working surface of the coated cemented carbide, wear resistance is not high, and JYS casting production of composite board hammer at a high manganese steel cast-matrix is extremely dense toughness, hardness only to diamond tungsten alloy, can resist harsh abrasive wear.

Alloy plate Blow bars

Adding a small amount of a variety of high chromium cast iron alloy and trace elements for the production of crusher hammer, make the product wear resistance and mechanical properties are improved to a large extent, the performance was excellent customer appreciation.

Impact crusher liner

Crusher liner is generally made of high manganese steel casting, many shapes crusher liner, there are two types of broken line and arc-shaped. Mansard counterattack on the back plate surface enables each point materials are approximately perpendicular to the direction of impact, so for optimum crushing effect. Arcuate surface enables counterattack gob after a rebound out of the back plate, the center region is formed in the intense impact grinding zone, in order to increase the impact of free material crushing effect.

Hubei JYS is a professional impact crusher parts manufacturers, advises clients in the choice counterattack broken boards hammer, first select a perfect quality of the manufacturers, which can greatly reduce the cost of production of high-chromium alloy plate hammer, but also saves board hammer replacement time and improve production efficiency.

Please contact us with you requirement or if you do not see the part you need listed above. vip@jinyangshi.com, +86-0717-3286139 .

PERFORMANCE CHARACTERISTICS

-

COMPETITIVE PRICES

The company has a captive power plant and foundry sand, low production costs, factory outlets, a strong price advantage -

BETTER QUALITY

Crusher wear parts are produced at our own foundries and manufacturing facilities. As a result, we have complete control over quality at every step of the process, from the selection of raw materials right on through to final production. -

HIGH EFFICIENCY

99% qualified rate of spare parts, 97% qualified rate of finished products, 99% qualified rate of finished products left fty,Processing rate of customer feedback is up to 100% -

CUSTOM CASTING

Supplying Custom Wear Parts for Mining Machinery, Mixing Plant and Construction Equipment

TECHNICAL PARAMETER

| model |

size (mm) |

feed opening (mm) |

max feed size (mm) |

capacity (t/h) |

power (kw) |

weight (t) |

(mm)Size (L*W*H) |

| PF-1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 37-45 | 12 | 2330×1660×2300 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 45-55 | 15 | 2370×1700×2390 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 110 | 17.7 | 2680×2160×2800 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 100-180 | 132 | 22.4 | 2650×2460×2800 |

| PF-1315 | Φ1320×1500 | 860×1520 | 500 | 130-250 | 220 | 27 | 3180×2720×2620 |

| PF-1520 | Φ1500×2000 | 830×2040 | 700 | 300-550 | 315-400 | 50.6 | 3959×3564×3330 |

| PF-1820 | Φ1800×2000 | 1260×2040 | 800 | 600-800 | 630-710 | 83.21 | 4400×3866×4009 |

ENTERPRISE STRENGTH

The company has two sand production line, a V-method casting production lines, an EPC production line, a machine shop; 2 5T electric furnace, two 3T intermediate frequency electric furnace, 2 1T intermediate frequency electric furnace, the largest can do 12 tons of castings, annual production capacity of 15,000 tons or more, to create South Africa's largest wear-resistant materials production base.

GLOBAL COOPERATION

Dialogue with international, multinational construction group, the company has an independent import and export business qualification, and long-term exchanges and cooperation overseas countries, not only the company's products to maintain a high level, and won wide international market, the products are exported to Russia, Kazakhstan Stan, Turkey, Saudi Arabia, South Africa, Vietnam, India, the United States, Australia and other 30 countries and regions.

SPECIAL REMINDER

Hubei JYS new wear-resistant materials Co., Ltd. is a specialized manufacturer of wear-resistant castings, mainly engaged in high manganese steel, high chrome, wear-resistant alloy steel castings, the annual provision of other manufacturers of spare parts processing business, no matter what the manufacturers what models wear castings, as long as you can provide drawings, samples or molds, we can produce!

Tel: +86 0717-3286139 E-mail: vip@jinyangshi.com